WIDE WEB

FW PLC-SERIES

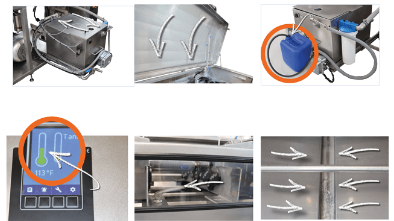

FW Anilox Cleaners for Wide Web applications are built with a PLC control to enable the user to easily change the temperature, rotation speed and washing time.

The FW PLC Anilox Cleaners clean larger and heavier rolls and sleeves. All of these cleaners can be customized to your specifications. Such options are adding an adapter to clean sleeves safely, an extraction system to clean more aniloxes per wash, or reinforcing the machine to clean even heavier rolls.

Wide Web Product Catalog