Cleaning plates properly and in a gentle and safe way is essential. Damaged plates due to improper cleaning not only are expensive to replace, but slow down your production. How do you choose between manual cleaning or an automated cleaning system?

There are two types of cleaning

Both manual cleaning and automated cleaning are well-known in the industry, but which method is the best and most cost-efficient for your company? Clean, intact plates ensure proper print quality.

Area sales manager, Mette Laursen, at Flexo Wash explains the pain of a broken plate perfectly:

“Plate cleaning equipment in general is not seen as something you make money on - only the presses do. But when it comes to plate cleaning it should be different, because one of the biggest pains for print houses is when the press is not running and that is very very costly.”

Laursen continues:

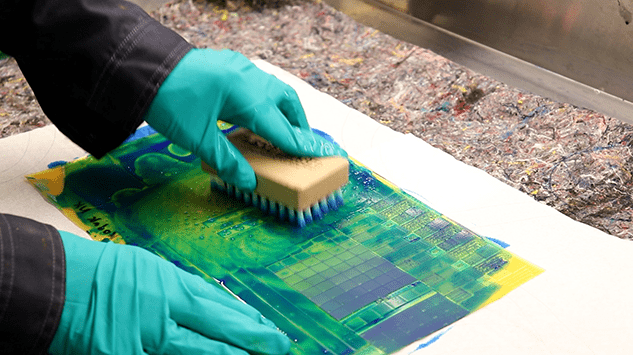

“Everyone wants to do everything they can to avoid this. It is very critical, when the press is running and you find out that there is a mistake in the print job - this can of course be caused by several different things, but one of them is a broken plate that is either broken by cleaning it too hard manually or maybe also the plate has not been cleaned properly. Cleaning plates manually sounds easy but in fact it is not. It is very difficult to make sure you have an even pressure all over the entire plate and damaged plate is costly.”

PLATE WASHING - ALL YOU NEED TO KNOW

The Pros and Cons

There are benefits to both manual cleaning and automated cleaning and one method does not exclude the other. The choice is more dependent on what your specific needs are. At Flexo Wash we are experts in creating the best cleaning solutions and we provide you with honest information, so you can make the right decision.

Automated Cleaning

- Effective and constant cleaning flow

- Limited manpower needed

- Effective cleaning of all types of inks

- Ensures high-quality cleaning of all plate’s surfaces

Cons

- Larger start-up investment

- Requires space

- System requires maintenance

Manual cleaning

Pros

- Low or no start-up investment

- Requires less space

- Well-known method

Cons

- Inconsistent cleaning quality

- Risk of damaging plates

- Time consuming

- Downtime on press due to unclean or damaged plates

We provide a complete solution.

When it comes to plate cleaning, we strongly recommend that your main cleaning process is automated. The process is very simple, but with a machine you avoid many broken plates because of incorrect pressure.

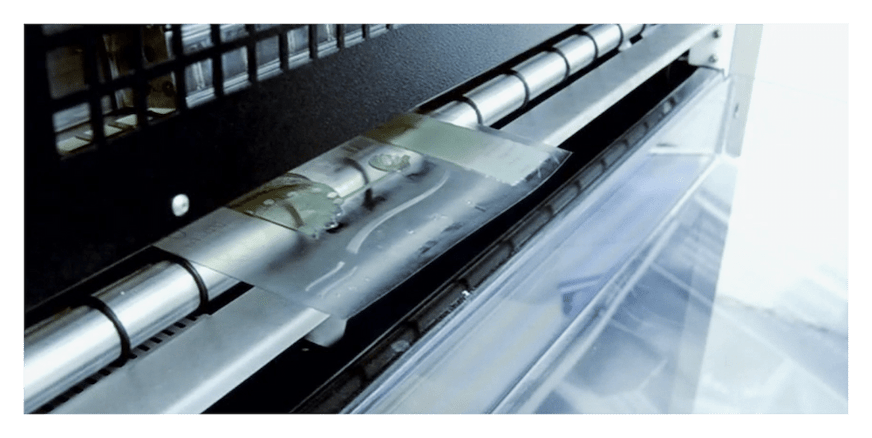

The automated cleaning is eco-friendly and consists of three parts: washing, rinsing and drying. After the print job, all plates are placed on the conveyor belt, which automatically takes them through the entire wash process.

Using the eco-friendly cleaning liquids from Flexo Wash, the plate washers are specially developed to efficiently remove the different types of inks from the plates in only a few minutes.

The machines are made of stainless steel and other highly resistant quality materials, which ensures a long lifetime of the product and a very low degree of maintenance.

If you want to know more about how an automated cleaning system can help your printing business, then download our guide “Manual or Automated plate cleaning” – click here.