The LaserX Series promises all the same safe and high-quality cleaning, but twice as fast as the immensely popular regular Laser Anilox Cleaners from Flexo Wash. This is an optimal choice for printers wanting to invest in reduced cleaning time and new technology from a trusted company.

All the Flexo Wash Laser Anilox Cleaners are available in the LaserX option. Flexo Wash offers four LaserX Anilox Cleaning models for cleaning lengths up to 147” with the largest model.

For even faster laser anilox cleaning —go LaserX2!

For customers with an even greater need for speed without compromising safety and cleaning quality, Flexo Wash is launching LaserX2, which is four times faster than the regular Anilox Laser Cleaner and twice as fast as the LaserX.

The two new models include the following machines:

- FW 850 Laser/LaserX

- FW 2000 Laser/LaserX/LaserX2

- FW 3000 Laser/LaserX/LaserX2

- FW 4000 Laser/LaserX/LaserX2

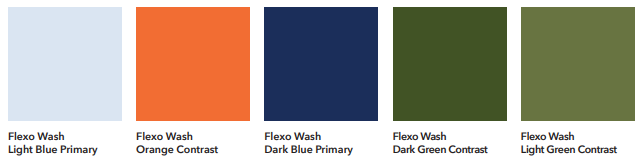

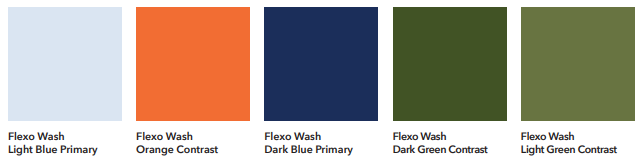

As a special feature, North American customers can choose the color for the exterior of their new LaserX Anilox Cleaner. Flexo Wash now offers six standard exterior color options plus the ability to customize the color.